Technical Specifications

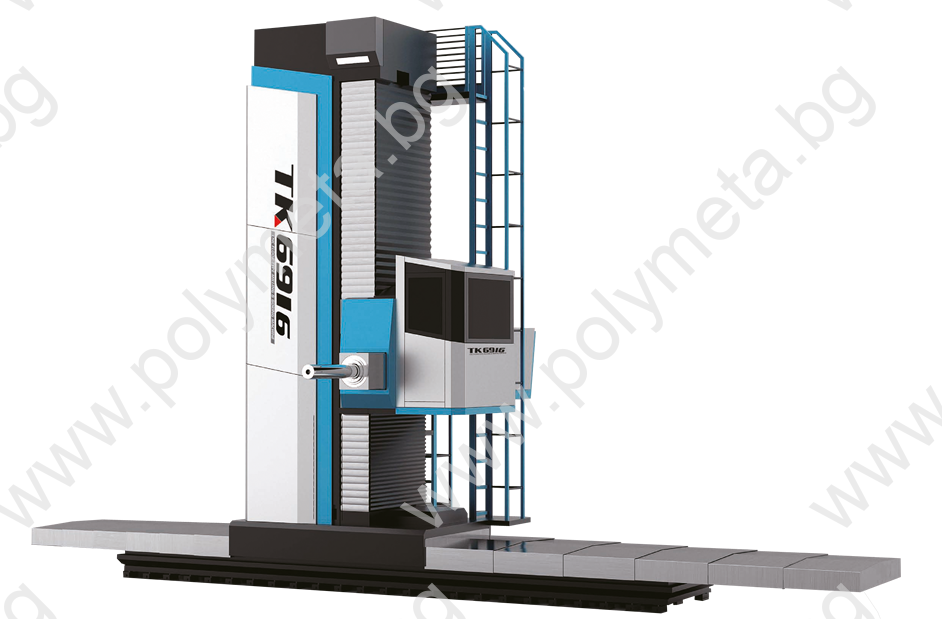

| MODEL | ТК6913 | ТК6916 | ТК6920 | |

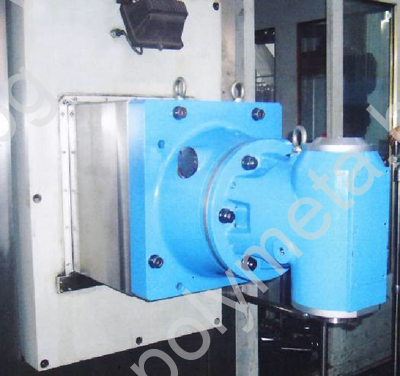

| Boring spindle diameter | mm | 130 | 160 | 200 |

| Milling spindle diameter | mm | 221.4 | 280 | 320 |

| Spindle end | ISO50 | ISO50 | ISO60 | |

| Ram dimensions | mm | 350х380 | 440х480 | 480х520 |

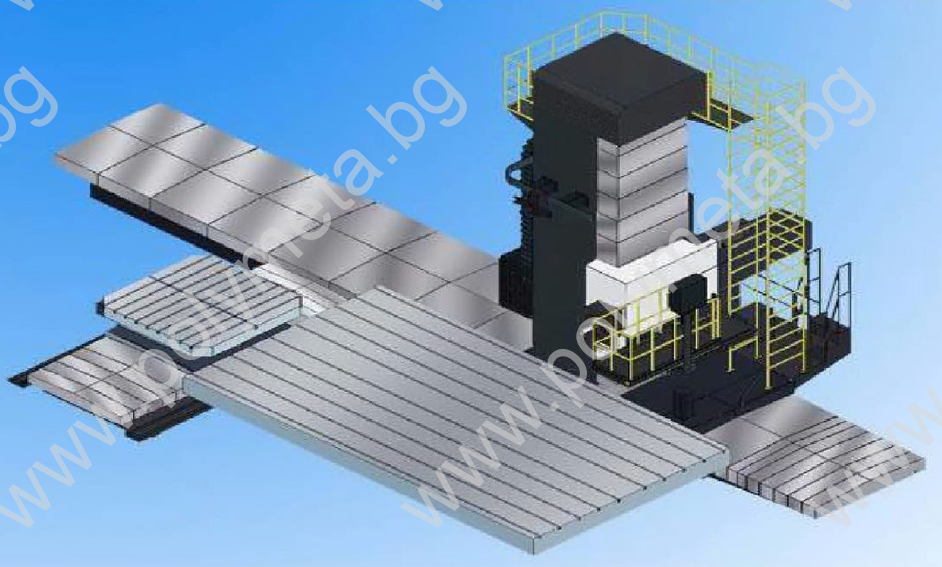

| Column longitudinal travel (X axis) | mm | 4000х20000 | 6000х20000 | 8000х20000 |

| Boring head vertical travel (Y axis) | mm | 2500х4000 | 2500х5000 | 3000х7000 |

| Spindle travel(Z axis) | mm | 800 | 1100 | 1200 |

| Ram travel(W axis) | mm | 600 | 900 | 1200 |

| Total cross travel (Z + W) | mm | 1400 | 2000 | 2400 |

| Spindle speed (two ranges) | rpm | 3.15-800 | ||

| Z-axis and W-axis feed rates | mm/min | 0.5 – 2000 | 1-2000 | 1-2000 |

| Column longitudinal speed (Х-axis) and boring head vertical speed (Y-axis) | mm/min | 1-2500 | ||

| Positioning accuracy (X/Y/Z/W) | mm | 0.025/1000 | ||

| Main motor power | kW | 37 | 55 | 7 |

| Weight | t | 60 | 85 | 130 |

Note: The exact parameters of the technical specification, including those that differ from the ones above, are agreed before making an order and signing a contract.