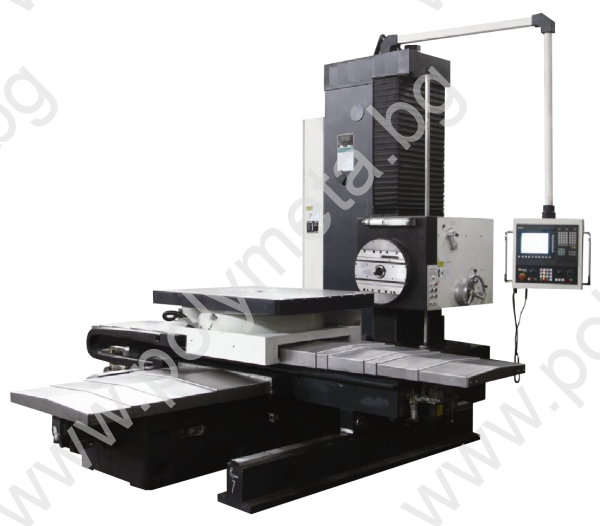

Technical Specifications

| Model | ТК611С/1А | ТК611С/4А | ТК611/С1 | ТК611/С4 | |

| Spindle diameter | mm |

110 |

|||

| Work table | mm |

1320 х 1010 |

|||

| Work table control | CNC control | Manual control | |||

| Table load | kg |

5000 |

|||

| Distance from spindle axis to table surface | mm | 5-835 | 5-1135 | 5-905 | 5-1205 |

| Table strokes (X,Z) | mm | 1200 х 1300 | 1800 х 1300 | 1200 х 1300 | 1800 х 1300 |

| Headstock vertical travel (Y) | mm | 830 | 1130 | 900 | 1200 |

| Spindle travel (W) | mm |

550 |

|||

| Max. boring diameter | mm |

240 |

|||

| Max. drilling diameter | mm |

50 |

|||

| Spindle end |

ISO50/BT50/ |

||||

| Max. spindle torque | NM |

1100 |

|||

| Max. face plate torque | NM |

1100 |

|||

| Max. spindle axial effort | N |

13000 |

|||

| Face plate tool holder’s radial travel | mm |

160 |

|||

| Max working dia. of face plate tool holder | mm |

630 |

|||

| Spindle speed /stepless/ | rpm |

12 – 1100 |

|||

| Face plate speed /stepless/ | rpm |

4 – 125 |

|||

| Main motor power | KW | 15 | 15 | 11 | 11/15 |

| Spindle feed rate | mm/min |

0,5 – 1000 |

|||

| X, Y and Z-axis rapid travel | mm/min |

5000 |

|||

| Spindle rapid travel (W) | mm/min |

3600 |

|||

| Rapid travel of face plate tool chuck | mm/min |

1180 |

|||

| Positioning accuracy (X, Y, Z) | mm |

X: 0.04, Y: 0.04, Z: 0.04 |

|||

| Repeatable positioning accuracy (X, Y, Z) | mm |

0,015 |

|||

| Table rotation accuracy | mm | 15″ /indexing 0.001º, 1º or 5º/ | +/- 6″ (4 x 90 º) | ||

| Repeatable table rotation accuracy | mm | 5″ | 5″ | +/- 3″ (4 х 90 º) | |

| Machine overall dimensions | mm | 5347 х 3020 х 2890 | 5016 х 3867 х 3148 | 5347 х 3020 х 2890 | 5347 х 3420 х 3190 |

| Weight N.W./G.W. | kg | 1200 / 1350 | 1700 / 1900 | 1200 / 1400 | 1550 / 1750 |